Hot sale Heat Resistant Silicone Aluminum Paint - Crowbar/Chopper Resistor – Wepower

Hot sale Heat Resistant Silicone Aluminum Paint - Crowbar/Chopper Resistor – Wepower Detail:

█ Application

Crowbar resistor is mainly used in low voltage ride through technology of wind power inverter. It is used at the rotor side of wind turbine generator to bypass the rotor side converter. In case of low voltage disturbance in the power grid, the DC bus voltage and rotor current shall be prevented from being too high. It mainly works in fault state to damp stator flux linkage. Crowbar resistors can dissipate huge amounts of energy instantaneously.

It is mainly used in the frequency conversion / converter system of doubly fed variable speed constant frequency generator units to improve the low voltage ride through capability of generator units, which is limited by the power grid

Large current impact caused by voltage drop protects excitation converter and limits rotor winding over voltage.

█ Feature:

The resistance material is imported alloy steel, which can absorb large energy impact in a short time, and can meet different power requirements.

█ structures:

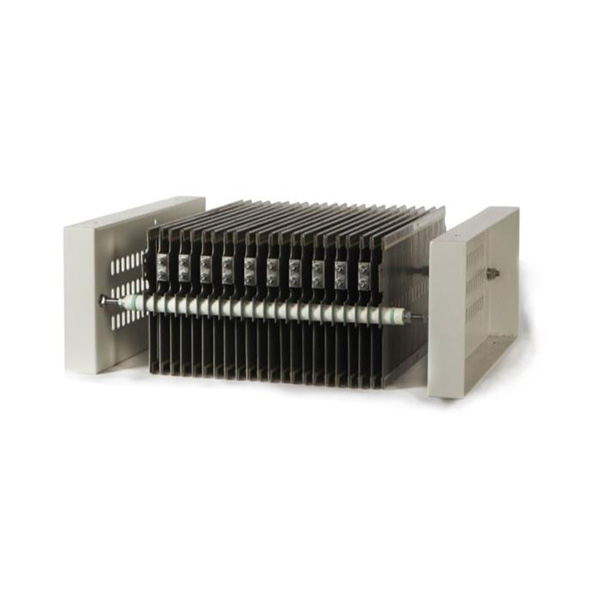

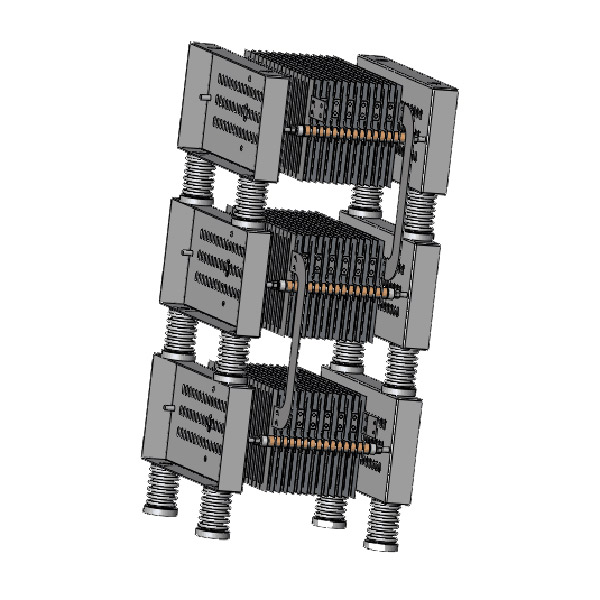

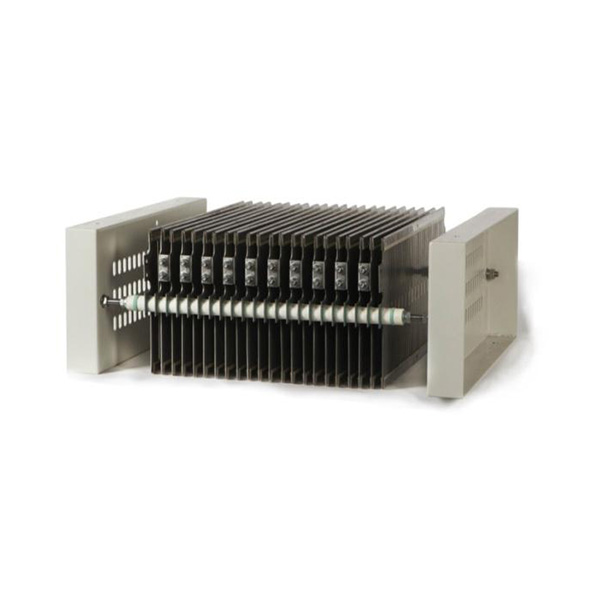

Mica sandwich structure, traditional metal carrier grid structure and block carrier structure:

1. mica sandwich structure, with small volume, low cost and large heat capacity, is suitable for absorbing large energy in a short time and for single impact at long intervals (once a week).

2. with the traditional metal grid structure, the product has relatively moderate volume, relatively moderate cost and good heat dissipation performance. It is suitable for multiple impacts in a short time (once every 30 minutes). It can be used in crowbar resistor, chopper resistor and braking resistor circuits.

3. block carrier structure, the product has strong impact resistance and good heat dissipation performance. High structural strength and moderate price. Suitable for short-time multiple impact. It can be applied to crowbar resistor, chopper resistor, braking resistor and other circuits.

█ Life Time of Crowbar Resistor

| 200J | 1 times/second | |

| 220KJ | 1 times/30mins | 35000 times(20 years of life) |

| 640KJ | 1 times/week | 1000 times(20 years of life) |

| 1360KJ | 1 times/month | 260 times(20 years of life) |

| Take 1.5MW windmill generator as an example, environment temperature ≤ 60℃ | ||

█ Resistor Material Comparison

|

Material |

(g/mm3) |

(Ω·mm2/m) |

J/(g·K) |

W/(m·K) |

ppm/℃ |

|

SUS304 |

7.9 |

0.72 |

0.5 |

13.2 |

≤1400 |

|

SUS316 |

7.93 |

0.78 |

0.45 |

13.23 |

≤900 |

|

SUS310S |

7.98 |

0.88 |

0.46 |

13.2 |

≤600 |

|

Cr20Ni80 |

8.4 |

1.09 |

0.441 |

16 |

≤100 |

█ Selection Table

|

Energy |

Resistance |

Time |

Dimension(mm) |

||

|

(L)mm |

(W)mm |

(H)mm |

|||

|

50KJ |

3R |

30mS |

420 |

160 |

95 |

|

200KJ |

2R |

3.8S |

285 |

178 |

150 |

|

500KJ |

3.3R |

3.8S |

670 |

150 |

150 |

|

1.0MJ |

0.36R |

0.1S |

395 |

190 |

153 |

|

1.5MJ |

0.45R |

3S |

520 |

292 |

100 |

|

2.0MJ |

0.4R |

30mS |

868 |

175 |

130 |

|

2.0MJ |

0.5R |

30mS |

943 |

195 |

135 |

|

2.2MJ |

0.7R |

1S |

446 |

240 |

153 |

|

2.5MJ |

0.95R |

3S |

597 |

400 |

200 |

|

3.0MJ |

0.7R |

1S |

432 |

240 |

153 |

Note: For other technical parameters & requirements, please contact with our company’s business man.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Hot sale Heat Resistant Silicone Aluminum Paint - Crowbar/Chopper Resistor – Wepower , The product will supply to all over the world, such as: Bangkok, Mexico, Durban, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.